The development history of pulp tray

Pulp tray, also known as pulp molding, is a new type of environmentally friendly material that uses plant fiber as the main raw material and is molded by mold. Its development history dates back to the early 20th century, and the following is an overview of the development history of paper brackets:

1. ** Origin ** : Pulp molding technology was first pioneered by Denmark in 1917, and Denmark began to use machine molding pulp molding products in 1936.

2. ** Development ** : In the 1950s, Italian engineer Enzo Michelin developed a new pulp molding process and obtained a patent. This process uses waste paper converted into pulp, which is then moulded to create a product with a specific shape and strength.

3. ** Global application ** : By the late 1930s, some companies in Canada, France, the United Kingdom, Singapore, and the United States, Japan, and Denmark have launched pulp molding products packaging production lines, and formed a larger production scale.

4. ** China's development ** : China's pulp molding industry started late, about 1984, Hunan pulp molding factory introduced the world's most advanced production line, mainly used for the production of egg trays. Subsequently, Liaoning, Sichuan, Jiangsu, Beijing and Shandong have introduced pulp molding production lines.

5. ** Technological progress ** : In 1988, the first domestic pulp molding production line developed by Nanjing Light Industry Research Institute and Jiangyin Machinery Factory No. 5 was identified and put into use, opening the pioneer of pulp molding machinery localization.

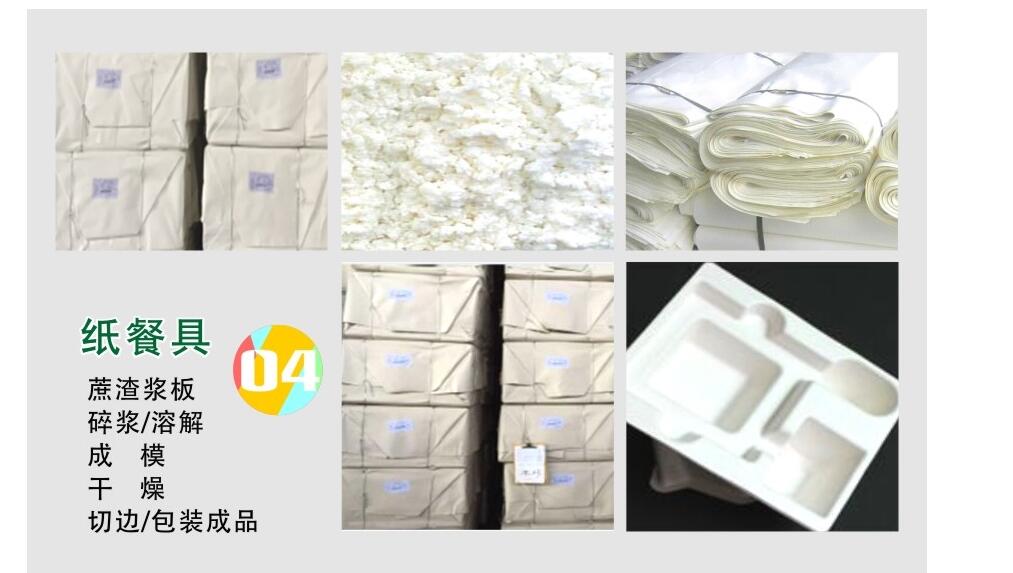

6. ** Market expansion ** : With the improvement of global awareness of environmental protection, pulp molding as an environmentally friendly and economic manufacturing process, its application field continues to expand, including food, medicine, industrial products, agricultural products and other packaging.

7. ** Modern development ** : In recent years, pulp molding technology continues to progress, product structure is increasingly complex, tray structure configuration planning and carrying capacity analysis is particularly important. Although the Chinese paper pallet industry started late, it has developed rapidly, from the initial dozens of manufacturers to the present more than 800, and the products have also developed from simple eggs and fruit packaging to industrial instruments, electronic components, household appliances and other high-end product lining packaging.

8. ** Facing challenges ** : Despite the rapid development, China's paper pallet industry still faces some challenges, including the instability of material property parameters, the lack of unified test methods and performance evaluation standards, and the lack of basis for planning.

9. ** Future direction ** : Paper packaging is developing towards the direction of heavy-duty packaging products, and large pulp molding logistics palleys have been developed, providing an effective way to achieve paper instead of wood packaging.

As an environmentally friendly material, paper holder has received more and more attention in the packaging industry because of its degradable and recyclable characteristics. With the progress of technology and the demand of the market, the development prospect of paper holder is broad.

Hot

Newest

- 联系我们果博东方在线开户客服电话:19038688886

- 2024-August Shanghai Packaging Exhibition

- The impact of plastic waste

- The difference between dry pressing process and we

- The development history of pulp tray

- KINYI Hong Kong printing and packaging exhibition

- Kinyi has recently passed BSCI certification

- Kinyi New biodegradable test report

- Kinyi 2024 New Year's Day Holiday Notice

- Kinyi Biodegradable Paper Pulp Planters

- Kinyi 2022 Chinese New Year Hoiday Notice

- The Production Process of Molded Pulp Packaging

- Molded Pulp Packaging -Waste to Treasure